Exhibition Overview

From November 25th to 27th, 2025, the three-day 2025 International Surface Treatment Exhibition was grandly held at the Shanghai New International Expo Center. As the annual grand event of the surface treatment industry in the Asia-Pacific region, this exhibition attracted more than 300 surface treatment-related enterprises from over 30 countries and regions worldwide. The exhibition area exceeded 50,000 square meters, and the number of professional visitors exceeded 20,000. With the theme of “Empowering Manufacturing Upgrade, Leading Green Surface Treatment”, the exhibition set up core exhibition areas such as electroplating and finishing, coatings and painting, and environmental protection equipment and technology. During the same period, several high-end forums were also held, focusing on cutting-edge directions such as new energy vehicle surface technology and chip electroplating processes, providing an important platform for technical exchanges and business matchmaking in the industry.

Company’s participation in exhibitions

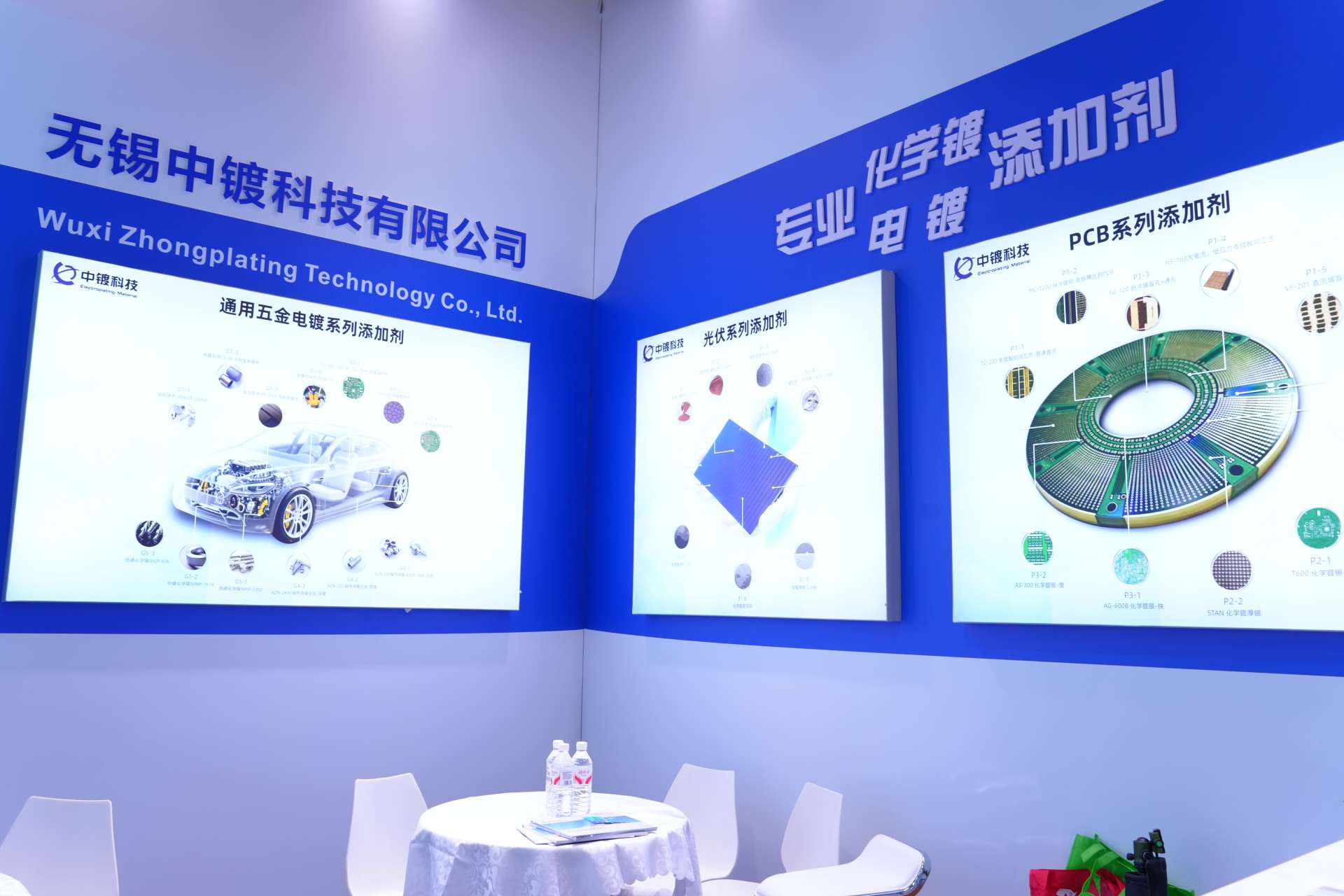

Wuxi Zhongdu Technology Co., Ltd., as an innovative force in the domestic surface treatment industry, showcased its technological achievements at this exhibition. The company’s booth, located at No. J01 in Hall E1, comprehensively presented innovative solutions in the fields of photovoltaics, PCB, semiconductors, and electronic electroplating through various forms such as physical demonstrations and on-site technical exchanges. During the exhibition, the company’s booth received more than 500 professional visitors from both domestic and overseas, including technical leaders and procurement representatives from several industry-leading enterprises. Over 20 cooperation intentions were reached on site, achieving fruitful results from the exhibition.

Key exhibiting products and technological highlights

Photovoltaic industry application products

At this exhibition, Zhongdu Technology highlighted its self-developed comprehensive solution for photovoltaic copper electroplating technology, encompassing high-precision electroplating solutions and accompanying precision electroplating equipment. This technology, through innovative additive formulations and pulse electroplating processes, can notably enhance the photoelectric conversion efficiency of photovoltaic cells, reducing raw material costs by over 30% compared to traditional silver paste processes. The on-site demonstration of copper electroplated photovoltaic cell samples showcased metallization line widths below 20 microns and adhesion forces exceeding 5N, garnering significant attention from leading photovoltaic companies such as Tongwei and Longi. According to the company’s technical leader, this process has been implemented on the mass production lines of multiple domestic photovoltaic enterprises, producing over 1GW of high-efficiency photovoltaic cells.

PCB, semiconductor, electronic plating additives

In response to the high-end demands of the electronic information industry, Zhongdu Technology exhibited a series of high-precision electroplating solution products, including the MC-1200 pulse copper plating process applied to semiconductor packaging. The MC-1200 pulse copper plating process utilizes a unique additive system, enabling uniform copper plating on high aspect ratio circuit boards with a thickness deviation of the plating layer controlled within ±5%, significantly enhancing the speed and integration of chips.

Hardware electroplating additive

Focusing on high-end hardware fields such as automotive components, Zhongdu Technology showcased a series of additive products including acidic zinc-nickel alloy and alkaline zinc-nickel alloy. Among them, the acidic zinc-nickel alloy coating exhibits a salt spray resistance of over 1000 hours and a corrosion current density below 0.1μA/cm², significantly enhancing the corrosion resistance and service life of automotive components. This series of products has been certified by international Tier 1 suppliers such as Bosch and Brembo, and is widely used in surface treatment of key components such as automotive chassis and brake systems.

Highlights of technological innovation

At this exhibition, Zhongdu Technology highlighted three major technological innovation highlights: First, through industry-university-research cooperation with teams from Shanghai University and Xiamen University, a low-energy electroplating process was developed, which reduces energy consumption by more than 25% compared to traditional processes; second, an independently developed intelligent electroplating control system, which enables real-time monitoring and automatic adjustment of plating solution components, and improves the control accuracy of plating thickness to ±3%; third, all series of products comply with EU RoHS and REACH standards, among which environmentally friendly processes such as cyanide-free electroplating and low-chromium passivation have already met future environmental regulations in advance. These innovative technologies reflect the company’s leading position in the field of green and intelligent surface treatment.

Industry influence and cooperation exchange

Key customer communication

During the exhibition, Zhongdu Technology engaged in in-depth technical exchanges and business negotiations with multiple industry leaders. The company’s management team discussed with technical leaders from companies such as CATL and Huawei Devices on topics such as the latest application progress of photovoltaic copper electroplating technology and innovative directions for semiconductor packaging electroplating processes, and reached multiple cooperation intentions. In addition, the company established contacts with several overseas customers, laying the foundation for expanding into the international market.

Development vision and outlook

Through this exhibition, Zhongdu Technology fully demonstrated its technical strength and innovative achievements in the field of surface treatment, further consolidating its industry position. Looking ahead, the company will continue to uphold the concept of “integrity, efficiency, and win-win”, focus on the surface treatment needs of strategic emerging industries such as photovoltaics and semiconductors, increase R&D investment, deepen industry-university-research cooperation, and prioritize the development of low-energy consumption, low-pollution green electroplating technology and intelligent electroplating equipment. We strive to become a world-class provider of high-end electronic chemicals and surface treatment solutions, contributing to the high-quality development of China’s manufacturing industry.

Summary

Participating in the 2025 International Surface Treatment Exhibition is a crucial step for Zhongdu Technology to expand its market and enhance its brand image. Through this exhibition, the company not only showcased its latest technological achievements but also met numerous potential customers and partners. Additionally, it gained a deeper understanding of industry trends and market demands, providing direction for future product development and market expansion. The successful participation in the exhibition will further propel Zhongdu Technology’s innovative development in the surface treatment industry, aiding the company in achieving its strategic goal of becoming a globally leading provider of green surface treatment solutions.